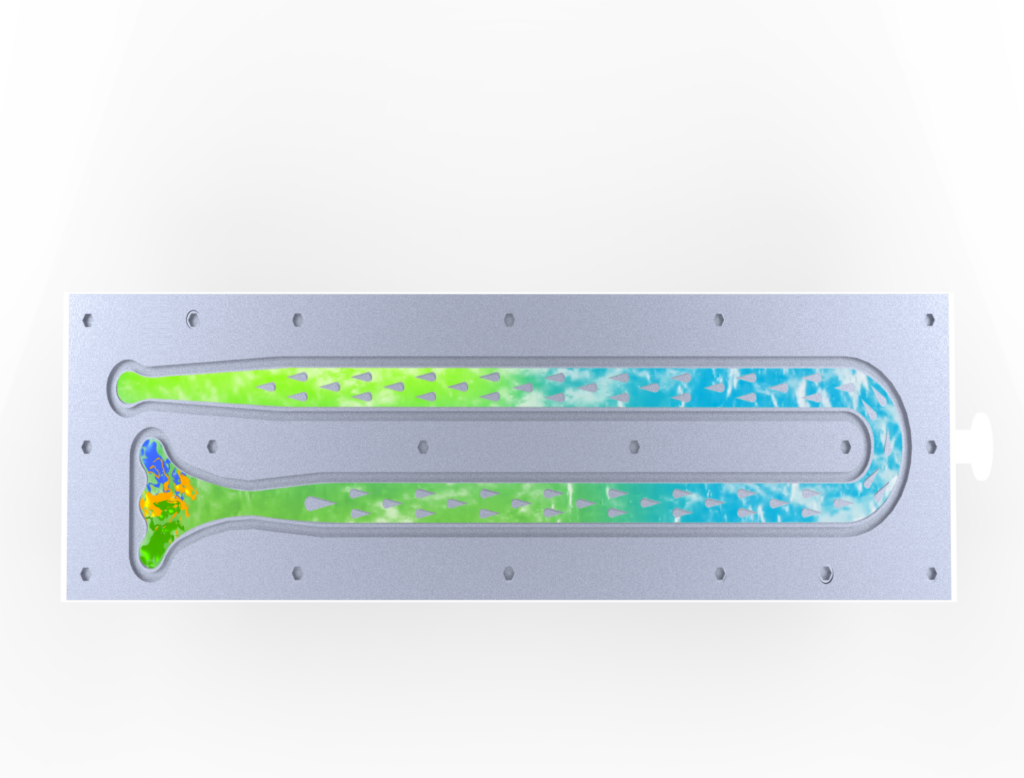

he reactants enter the plate reactor from different inlets and converge into a single laminar flow. Obstructions configured in the flow passage at designed intervals produce desired mixing while maintaining PLUG flow as well as avoiding any dead zones.

REACTOR MOC: Austenitic SS, Martensitic SS, Hastelloy, Inconel, Monel, Titanium, Filled PTFE , Borosilicate Glass for Photochemical reaction

Heating / Cooling: External jacket, Ceramic Heaters, Induction Heating.

Chemical Processes: Sulfonation, Chlorination, Hydrogenation, Photo Halogenation, Nitration, Oxidation, Sulfoxidation etc.